Working of Vacuum Filtration

During use, an industrial vacuum cleaner generates dust, particles and materials with different granulometry. It is essential that the vacuum cleaner retains all these materials inside and prevents them from being released back into the environment through the outgoing air stream.

Protecting the health of workers : Working of Vacuum Filtration

Breathing or being exposed for long periods of time to very fine or harmful dusts (such as silica dust or lead) causes skin and respiratory symptoms or problems.

Avoid contamination and comply with current regulations.

Minimize the possibility of explosion in hazardous areas or in the presence of combustible dust.

For this reason, the cleaning equipment used must be equipped with adequate progressive efficiency filtration systems, capable of blocking and retaining each type of dust.

Primary and Absolute Filters and Multi-Stage Filtration

It is difficult to choose the best filter to filter dust and particles and to ensure absolute safety in the workplace.

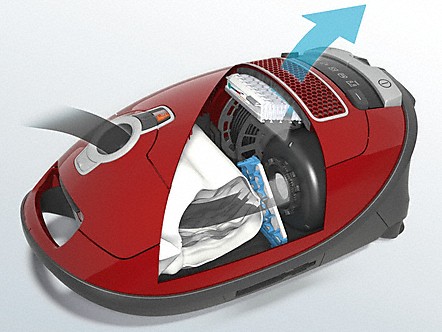

Delfin atex vacuum cleaner are equipped with high quality filters of different types depending on the use that is going to be given in the company. Unlike common vacuum cleaners, industrial vacuum cleaners are equipped with more than one filter inside, forming the aforementioned “multi-stage filtration” where several filters with different functions are used to ensure efficient and safe filtration.

The primary, or main, filter has the function of retaining most of the dust and material sucked in before it re-enters the environment. It has an additional function to protect the engine avoiding wear and problems.

Filters for dust collection can be class L, M or H and differ according to use, as we will see later.

To ensure greater filtration and protect the most crucial parts of the machine, Delfin supplies its vacuum cleaners with HEPA – certified absolute filters. Positioned near the head of the vacuum cleaner, they guarantee greater protection of the motor, extending its operational life and ensuring that even fine and potentially dangerous dust is collected.

Suitable dust and filters: How to choose?

The size of the particles that make up the material of the vacuum cleaner is essential to finding the right filter.

According to DIN -EN 60335-2-69 / 2015 and IEC 60335-2-69 / 2012, dust is classified into three main macro-categories according to the maximum concentration allowed in a work environment before they become harmful to operators: Class L (low), M (medium) and H (high).

Powder Formulation and Subdivision

Class L ≤ 1.0% Dusts with maximum permitted concentrations (MAC) > 1 mg/m³.

They represent a moderate risk for the operators and the filter used in this case retains more than 99% of the dust with a particle size down to 3 microns.

Class M < 0.1% Dusts with maximum permitted concentrations (MAC) ≥ 0.1 mg/m³.

Representing a medium risk, the filter retains more than 99.9% of dust with a particle size of less than 2 microns.

Class H < 0.005% Dusts with maximum permitted concentrations (MAC) < 0.1 mg/m³.

They represent a high risk, the corresponding filter retains more than 99.995% of dust with a particle size of less than 1 micron (including carcinogenic dust).

How filters are classified?

Depending on their frame, which guarantees a certain level of filtration, the filters are classified in turn into L, M and H.

The different classifications indicate which vacuum cleaner is best suited for the intended use.

Type L

The best vacuum cleaner with washable filter suck up 99% of dust up to 3 microns in size, they are used in general cleaning applications, which do not pose a high risk to health, such as plaster dust and sawdust from carpentry.

Vacuum cleaners with filter type M, capture 99% of dust down to 1 micron in size, cover a wide variety of applications, are mainly used in companies that require high filtration efficiency such as the food processing, pharmaceutical and surface treatment industries. The most common vacuumed dusts are ceramic, plastic, paint and food.

Vacuum cleaners with class H filter offer greater suction and filtration capacity than the previous ones, they suck up and capture up to 99.995% of dust with dimensions of up to 0.18 microns, they are generally used when working in environments with highly carcinogenic dust. such as lead, carbon, tar, nickel, cobalt, copper and silica.